Amarinth, a world-leading, net-zero designer and manufacturer of low lifecycle cost centrifugal pumps and associated equipment, primarily for the offshore and onshore oil & gas industries; nuclear and renewable energy generation; defence; desalination; process and industrial markets, has successfully delivered a state-of-the-art cryogenic pump replacement to Air Products at its Didcot facility in the United Kingdom.

Air Products, a global leader in industrial gases, sought a UK-based pump manufacturer capable of seamlessly replacing an obsolete Girdlestone single stage cryogenic pump used for transporting liquid argon at temperatures below –186°C. The application demanded a pump that was both dimensionally and hydraulically interchangeable with the legacy design, without compromising on performance or safety in extreme cryogenic conditions.

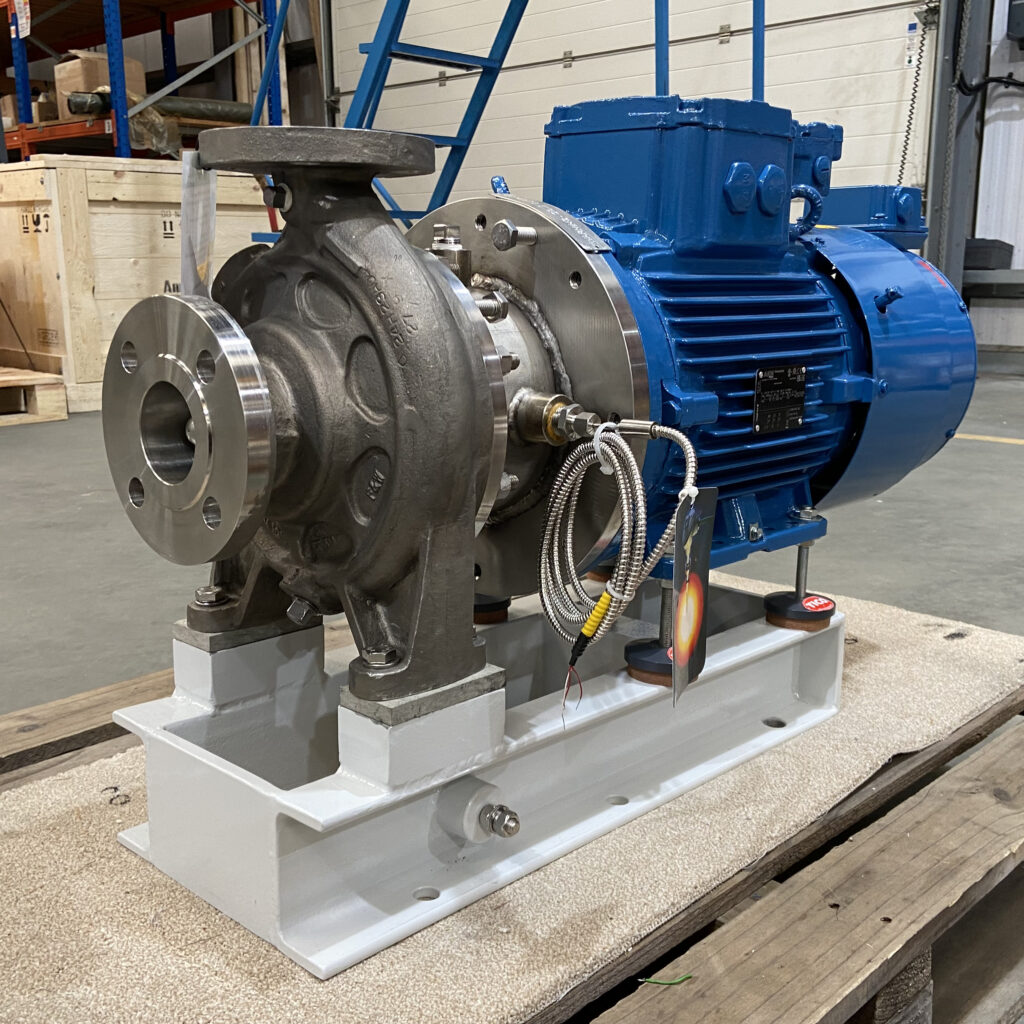

Amarinth has engineered a range of pumps that not only match the physical dimensions and hydraulic performance of the original Girdlestone models but also integrate modern design improvements. For this project, the pump was manufactured from carbon steel, a deliberate choice to preserve ductility in extreme cold conditions, as opposed to stainless steel, which becomes brittle at cryogenic temperatures. This careful material selection ensures structural integrity and enhances the durability of the unit.

The pump is powered by a high-performance WEG motor, ensuring efficient operation under heavy-duty conditions. Integrated PT100 pressure transmitters deliver precise pressure monitoring, while auxiliary heaters maintain optimal operating conditions for flawless performance in cryogenic environments. Additionally, a specially formulated paint system has been applied to the pump’s exterior to provide superior adhesion and resistance to the severe thermal stresses encountered in such applications.

Before delivery, the new cryogenic pump underwent comprehensive cold function testing using liquid nitrogen in a controlled environment at Amarinth’s dedicated test facility. These rigorous tests confirmed that the pump meets all performance parameters and is capable of reliably handling the severe operational demands of transporting liquid argon.

To ensure the solution was tailored exactly to the unique requirements of Air Products, Amarinth’s Head of Technical Engineering conducted an on-site visit to the Didcot facility. This collaborative approach enabled an in-depth evaluation of design parameters, allowing for fine-tuning of the pump to meet both safety and performance standards essential for cryogenic applications.

By designing pumps that are both dimensionally and hydraulically interchangeable with obsolete Girdlestone models, Amarinth offers a cost-effective and minimally disruptive solution for companies updating their legacy systems. Air Products’ decision to engage Amarinth was driven not only by the technical superiority of the replacement pump but also by the manufacturer’s expertise in developing cryogenic solutions for demanding industrial processes.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “In a world where energy transitions and technological innovation are accelerating at an unprecedented pace, this latest order from Air Products underlines our role as pioneers in engineering robust, future-ready solutions. Our commitment to sustainability, innovation, and operational excellence enables us to deliver sophisticated cryogenic pump systems that not only meet today’s demanding standards but also position our customers to thrive in tomorrow’s dynamic industrial landscape.”

Discover more from Inside Oil and Gas here…