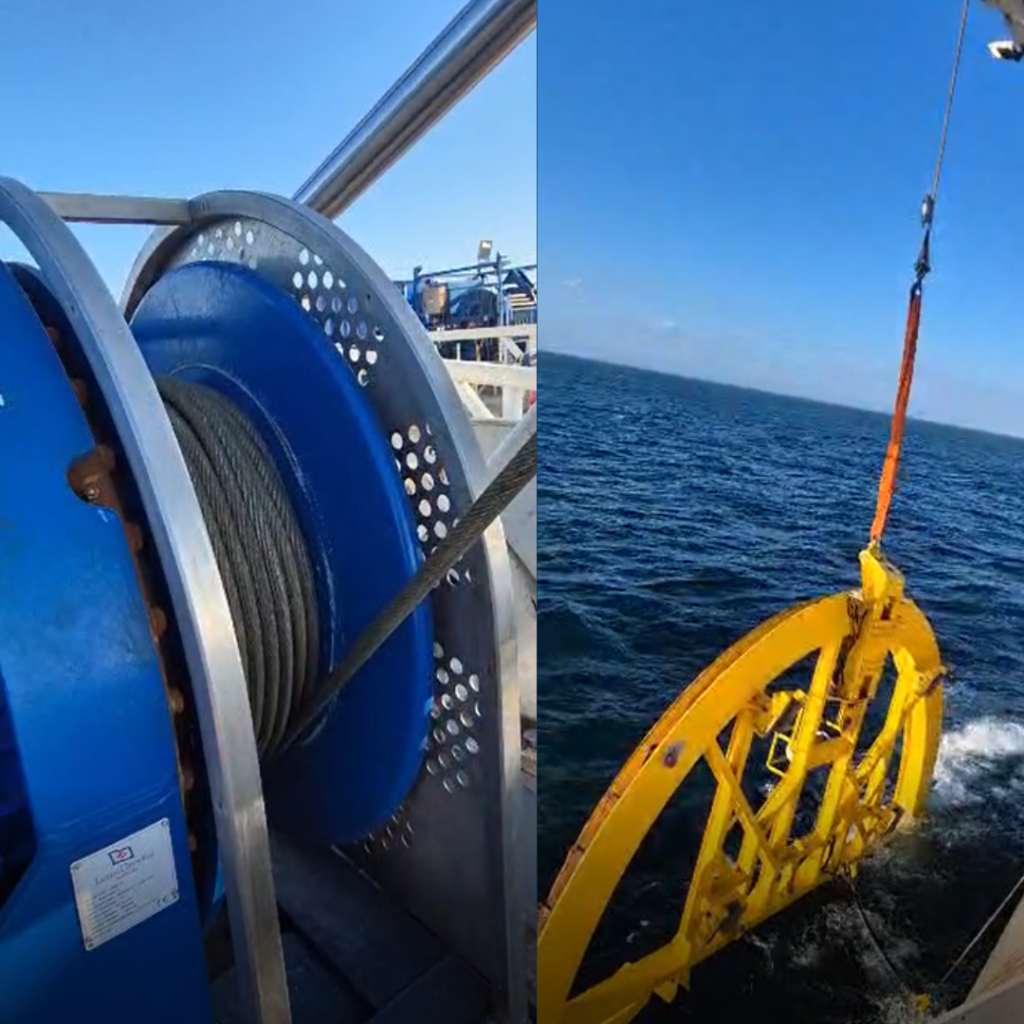

Scantrol’ s mTrack AHC Controller, combined with Bosch Rexroth’s Secondary Controls, ensures smooth and safe operation for TravOcean’s new 15-ton cable laying winch. This winch is used to lay wind turbine power cables on the seabed.

“We need Active Heave Compensation (AHC) to have a smooth operation and not to damage the cable during landing. The function increases the weather window and reduces the weather standby, making the process more efficient, with less downtime in challenging conditions,” explained Thomas Vannier, Technical Support Manager at the French submarine cable installation company, TravOcean.

TravOcean managed the entire installation and integration process on its own, with just a minimum of remote assistance from Scantrol. “We ordered the mTrack from Scantrol and received it on time. Our first task was to configure mTrack for our specific application and integrate it into our winch control system,” said Vannier.

The software engineers had prepared by attending Scantrol’ s online training, and with just a day of online support during sea trials, they were able to get the system ready for work.

“We did sea trials with ± 2 meters of movement on the sheave. We put a load on the hook of the winch and launched it 10 centimeters above the sea floor. We monitored this with the ROV, and the load did not move. It was great to see this performance, and we are very happy with the mTrack system. The winch has been operating every day with AHC engaged, and it continues to run smoothly without any issues. The system has exceeded our expectations and made the cable laying process much more efficient,” said Vannier.

TravOcean already has several winches with Scantrol AHC. Adaptability and responsiveness are important to TravOcean when operating in rough sea conditions.

“We have experience working with mTrack, but it was the first time we combined the system with Secondary Controls from Bosch Rexroth. Since this was a new winch design Scantrol assisted us with regards to communication between the PLC and the mTrack Controller. Despite the communication set-up and one day of support for the sea trial, our team was able to carry out the integration and installation on their own,” said Vannier.

“TravOcean’s experience with smooth AHC operation aligns perfectly with feedback we are receiving from other clients: the mTrack AHC controller consistently delivers smooth AHC performance,” added Rolf Krogh Hjelmeland, VP AHC & USV at Scantrol.

Read more news on energy from Inside Oil and Gas here...